1st Gen Toyota 4Runner Suspension and Tire Upgrade

From the 4x4 Rules of the Road:

"When approaching a four-way stop, the vehicle with the largest tires always has the right of way."

![]()

Contents:

- Introduction

- Suspension Installation

- Spring and Shock Specs

- Brake Proportioning Valve (LSPV-BV)

- Body lift and body mounts

- Epilog

- Summary

- Back to my 4Runner Cheap Tricks page.

![]()

Introduction:

When purchased, my '85 4Runner, it had stock springs that were badly rusted and sagging. In fact they had a nice reverse arch to them and the spring shackles were horizontal (pointing straight back)! The rear springs were riding on the overload leaf all the time, which probably contributed to the harshness of the ride.

The previous owner had installed a set of aftermarket Gabriel GasRyder shocks and the truck rolled on a set 4 nearly worn out (30x9.50) Bridgestone Desert Duelers. All in all, the ride was harsh and there was about 1" of clearance from spring to bump stop. All along I had intended to replace all that old rusty iron. I finally got around to it over the long July 4th weekend in 1997 when my company had a week-long shutdown.

![]()

Here's how I did it:

Phase I:

I was relatively new to Toyotas and 4x4s and opted for an off-the-shelf suspension package for my first shot at lifting my truck. In this case, I selected North West Off Road Specialties (NWOR) 3-1/2" System 2 lift package (p/n N71200) with the KYB 3-4" lift Gas-A-Just shocks (f:84341, r:84412), new u-bolts (which were not required), s/s brakelines, torque rod bracket, adjustable draglink, and a few other misc. parts. Everything arrived almost before I was ready for it, so it was time to get going...

Here is the view of my truck after the rear springs were swapped and before the front was touched. Unfortunately, I finished the back end before I thought of documenting the process. There's really not much to do in back, just support the frame on jack stands, remove the tires, pull the old springs off, and put the new ones on.

Check out the reverse arch action on those front springs. I've already sanded, primed, and painted the frame and added the ProThane polyurethane body mounts at this point. You can see the rusty patina on the differential pumpkin.

- Perhaps it was the rusty orange tint that lent its name to this component?

Jack it up, slide in some jack stands and yank the wheels. Now the fun begins! I actually began a few weeks before by soaking all exposed threads with WD-40 and I was able to get all nuts off intact and even re-use them! I needed a bit of heat and persuasion to get the steering damper off, though. A few of the spring shackle pins were badly rusted to the rubber bushings. I found that screwing a nut back on the pin and using a 2-1/2 lb. sledge hammer to persuade them to let go. On one, I found that by rotating the shackle while applying WD-40 also helped. I cleaned and sanded all the old pins and then coated them with NAPA Spray-on silicone grease. It is a very sticky green aerosol grease. So far no squeaks. The polyurethane spring and shackle bushings are grooved and therefore hold a lot of grease. When I get the time, I'm planning to replace all the pins with greaseable models.

Now's a good time to nuke that rust. All parts were cleaned of accumulated grease, rust sanded down to bare metal, primed with zinc-rich galvanizing primer and painted with a black epoxy paint.

Out with the old springs, in with the new! The greaseable spring pads (in between the leaves) are very cool.

Got the new springs on there, but that brake hose and drag link look to be stretched to their limit.

A new stainless steel brake hose does the trick. I also took this opportunity to completely flush the old brake fluid out. I used a one-man vacuum brake bleed setup and bled the front and rear lines after replacing the hoses. It took about 1 qt. of new brake fluid to flush out the old stuff. Don't forget forget to bleed the rear brake proportioning valve, too. While I was at it, flushed/bled the clutch hydraulics, too.

I noticed that the front brake pads were badly worn so replaced them a little later. I originally used an extended front torque rod bracket with the stock torque rod. It went on fine, but then later I noticed it was under compression when the vehicle was level. This was pre-loading the springs, twisting the axle back, increasing the wheel caster. I removed the stock rod and add-on bracket and replaced them with a Ranch adjustable torque rod. It has a threaded Heim joint on on end (urethane bushing on the other). You adjust the length so there is no pre-load at rest. It really improved the steering with less caster, its much more stable now.

And the finished project is pictured above. Note the new SuperLift dropped drag link, the dual steering stabilizers and torque rod bracket. This picture taken with the old 30x9.50 tires. The adjustable drag link is nice in that it allows for centering the steering wheel. For centering, just measure the distance the steering sector arm moves between wheels straight and steering wheel centered. The arm ends are 16 TPI, you can do the math. I have found it a little tricky to adjust/tighten properly, the rear seat seems to hang up before compressing the internal spring, resulting in loose steering. Plan on a few adjust/tighten/check cycles.

One trick I found with the dropped drag link was to tighten the screwed in end caps as tight as possible to cut down on the internal play. In the stock draglink, the ends are spring-loaded, but designed such that in either compression or tension, at most one spring is in play, on one end the spring is on the inside and on the other its on the outside. The dropped drag link use screwed in ends, which are identical, both with springs on the inside. So, under tension everthing is nice and tight, but in compression, the two springs compress and make for spongy turning input. To tighten the end caps really tight, I fashioned the tool pictured above out of 1x1/8" flat bar. The ends are filed down to about 0.84" to just fit the slot, then the tool is inserted in the slot and torqued down with a long Cresent wrench.

Unfortunately I didn't get any in-progress shots of the rear end work. Here is a shot of the left rear corner.

Here's a closeup shot showing the extended bracket for the brake proportioner and the new differential breather hose attachment. The extension bracket supplied with the NWOR spring set only has a 2-1/2" offset between the old and new holes (I assume for a 2-1/2" lift). Don't waste your money buying such a bracket. Its easy to make your own to exactly match your lift. Use a piece of 1/8" or 3/16" steel flat bar, ~1" wide, mark 2 holes to match the existing holes then measure up X" (where X" is the amount of your lift - measured before and after installing the springs) drill 2 more holes and get two small bolts to attach the sensing arm to the bracket and bolt the bracket to the axle. In fact if you are clever, measure off a series of holes spaced to match the existing hole spacing and drill them up the length of a longer piece of steel. Then you can adjust the sensing rod up and down in small steps as needed to get good front-rear brake bias. I noticed that the brake bias was still heavy on the front, (after stop-n-go driving, the front rims are hot, the rear are cool). Since the function of the valve is to sense a lightly loaded rear-end (i.e. the springs are high) and reduce rear braking, my extra 1-1/2" of lift simulates a light load. My final solution is pictured below.

For the vent, I simply removed the stock breather fitting and then ran a 1/8" NPT tap (greased) into the hole in the differential. Then I could use standard 1/8" pipe thread fittings. In back, I ran a straight fitting out of the axle, in front, I used a close nipple and a 45° elbow to point the vent towards the firewall. I installed separate vent lines and filters with short, uphill tubing runs to filters for each line. The front filter is high on the firewall, the rear vent on the tire carrier frame. Both are approx. 4' off the ground.

And the after shot. Still has the old 30x9.50 Bridgestone rubber on at this point.

And here it is w/ BFG 33x9.50 MTs, ready to rock and roll !!!

Phase II:

After a year of bolting on bumpers, fuel tanks, and other bits, I found I needed to fine tune the suspension.

- I felt I was too high and very tippy with narrow tires.

- The front end was not level, the passengers side was 1/2-1" lower due to the flatter spring there flexing more.

- The front spring shackles were digging into the frame under compression.

- Testing on my cheap suspension ramps confirmed my rear axle was only articulating about half what the front end was.

So I pulled the lift spring packs apart as well as the old stock spring packs. I cleaned everything up and began to play. In back, I took the main leaf from the lift pack (higher arch = more droop) and all the rest of the stock leaves and that is my new rear spring. It sits flat, just resting on the heavy overload leaf, but droops as far as the full lift pack did. I added 1.5" longer spring shackles and a 3 degree shim. The softer spring got me 1.5" more compression and the longer shackle added 1.5" more droop. However, the soft KYB shocks allowed the rear end to bottom out and they were too short for the added droop, so I swapped in a pair of RS-5143 shocks. They are a bit too long, so I added some 1.5" blocks to my cut-down bumpstops to protect the shocks.

In front, I used the first two lift leaves and added the lower stock leaves (1 on the driver's side, 2 on the passenger side) to level the front. I added 1.25" longer spring shackles to keep the springs off the frame. As a side benefit, my 33" tires no longer rub the wheel well under compression! A set of RS-5115 shocks up front handle the extra droop of the longer shackles.

All in all, I've lowered the truck 2 full inches from the original lift height. The front wheel wells were about 36" high stock (w/ 30" tires) and after the springs/tires/body lift was done, it measured 43" (7" total lift). Now it sits at 41", subtracting the 1" body lift and 1.5" larger tire height, I guess I have 2.5" lift springs now. And considering the longer shackles, its probably closer to 2".

Click here to see Phase-II of this project...

![]()

Spring and Shock Specs:

Springs:

While I had the springs off the truck, I decided to measure the spring rates. By turning the springs upside down and measuring the distance from the ground to the top of the spring (unloaded). Then, I stood on the spring and measured the deflection. Using this admittedly crude technique yielded the following rates:

- Stock - 260 lb/in.

- NWOR - 390 lb/in.

Conducting the same experiments on the various leaves led me to the conclusion that the bulk of the stiffness in the spring pack comes from the lower, shorted leaves. In fact, by swapping the stock lower leaves onto the higher arched, main lift leaves netted me a spring with the same 260 lb/in spring rate as stock with the added droop of the lift pack.

Below, I've summarized the specifications of the various spring leaves from the stock and NWOR 3.5" spring packs. The forward and rear dimensions represent the length of the spring in front of and behind the center bolt hole.

|

|

||||||||||||||||||||||||||||||||||||||||||||

|

|

Notes:

- Military wrap

- Tapered end(s)

Shocks:

KYB:

Here's some dimensions for the Gas-A-Just shocks that came with my 3.5" spring kit. The KYBs are a good shock on the road and for mild off-roading, like washboard gravel and dirt. I found that coupled with a stiff spring they are OK in heavier off-roading, but when I went to a softer spring, I started bottoming out more. Also, with the increased travel of the softer spring packs, I found the shocks were limiting my suspension droop because they were not long enough. Anyway, I ended up selling them after I switched to the Ranchos.

-

Front:

- KG5522

- 23.5" overall, 8.25" travel

-

Rear:

- KG5508

- 23.75: overall, 9.00" travel

Rancho:

I assembled and reformatted this Rancho shock selection table to make it easier to find shocks matching a given length requirement.

I used the following Rancho shcoks:[Return to the top]

![]()

Brake Proportioning Valve (LSPV-BV):

Disclaimer: This modification changes your vehicles braking system. This is what I have done and while it works for me, if you choose to follow these directions, do so at your own risk.

Most Toyota mini-trucks have front disk brakes and rear drum brakes. Drum brakes are "self-energizing" meaning that they are designed such that the brake shoes are forced into tighter contact with the drum under load. If you remember your bicycle with caliper brakes, notice how the front brake was stronger than the back one? This is because the front caliper is mounted in front of the fork and the arms are pulled forward under braking, forcing the brake pads to ride up the bevel on the rim, gripping that much tighter.

Disk brakes, on the other hand, move directly towards the brake disk, and are very linear in their braking force. So, on a vehicle with front disk and rear drum brakes, some sort of front/rear brake biasing is needed (less pressure to the rear, more to the front). So the LSPV-BV does this function with the Proportioning Valve component.

On a pickup, the weight on the rear axle can very greatly depending on what's in the bed. So, Toyota added a load sensing brake proportioning valve that tries to sense the load on the rear axle and vary the brake bias accordingly. At light loads, the bias is towards the front, to keep the rear wheels from locking. At heavy loads, the bias is moved towards the rear, to spread the braking force more evenly. This sensing is done via a rod attached between the axle and the valve (that is installed on the inside of the frame). As the axle is loaded, the frame and axle get closer together as the springs compress, making the lever move. The LSPV-BV does this function with the Load Sensing component, that is the sensing lever attached to both the valve and the axle.

One problem encountered when adding suspension lift to the rear axle, is that the valve senses this as a lightly loaded condition, and effectively cuts out the rear brakes. So, to compensate for this, an extension bracket needs to be installed to lift the point of attachment for the arm to compensate for the amount of lift. If you add 2" of lift, you should have a 2" extension bracket. This will move the arm back into the useable range of the proportioning valve. A simple bolt-on LSPV adjusting bracket is available here.

On my 4Runner, I did add a bracket initially, but after trying two different lengths, neither of which worked perfectly, I opted for a different approach. Since the 4Runner is like a partly loaded pickup (rear shell and rollbar) the rear axle loading is not subject to the variations of an actual pickup.

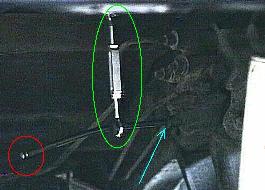

I removed the original extension bracket from the axle and my longer one, too, and cut the rod to the proportioning valve (circled in RED) and tied it to the body with an adjustable turnbuckle (outlined in GREEN). This is adjusted to keep the arm about 1/4-1/2" below the full up position. This setting seems to give a balanced front/rear brake bias. It also looks much cleaner back there with all that hardware on the axle gone. On the valve arm (pointed to by the BLUE arrow), the turnbuckle eye is sandwiched between two O-rings that fit tightly to keep it in place. The upper eye is attached to a metric-threaded screw-eye that fits nicely into a pre-threaded hole* in the bed.

* I'm truly amazed at the number of threaded holes Toyota saw fit to put in the 4Runner. I bet they could save 100 lbs. by removing all those welded in nuts and threaded inserts. But on the other hand, I've found many times that a conveniently located existing hole is right where I need it.

- Important Note:

- Doing this modication will eliminate the load sensing portion of the LSPV, since the sensing arm is no longer tied to the axle. I've found no change in braking with my 4Runner since doing this, but a 4Runner has a fair amount of weight over the rear axle, unlike a pickup. If running a pickup and you routinely carry full loads of cargo (as well as running with an empty bed) you may want to retain the LSPV to keep the brakes operating at peak effectiveness.

The final function of the LSPV-BV is as a Bypass Valve. What that does is to sense the front brake circuit pressure (via the 3rd brake line that runs up the frame rail to the passenger front corner). IF the front brake pressure falls too low, the Bypass Valve basically overrides the proportioning valve and send full brake fluid pressure to the rear brakes to ensure adequate braking in case of front brake loss.

[Return to the top]

![]()

Epilog:

In other words, how does it work?

Well, I have had the truck off-road a few times since installing the new suspension and I am very impressed with the performance. Here's a few pictures show you the capabilities from Hollister Hills.

The front bump stop is less than an inch from touching here. Also, check out my custom front valence. I've got the fog lights recessed behind wire mesh grills. It comes off in less than a minute with 2 1/2" grade 8 bolts and a single connector for the fog lights. It's now for available for someone who wants it, since I installed my new winch bumper.

I guess these stock rate NWOR springs are not as stiff as people say. It looks like they compress up nicely. Actually reminds me of the old springs in this shot.

When the front shackle swings back (touching the frame here), the front tire moves up and back. There is the slightest of rubbing occurring at the lower corner of the wheel well here. I've since trimmed a bit of the seam away from the inner well, flattened the rest of it out and tucked the wheel well liner behind the lower lip of the fender. An inch of body lift and 1.25" longer shackles seem to have completely eliminated the rubbing (with the 33x9.50 tires - my 33x15.50 Swampers still rub while turning - to solve this requires moving the axle forward). I was running 14 PSI front and rear here, under full load the tire flattens out nicely.

You'll notice the left rear is just off the ground, and below, you'll see the reason why.

I'm sure I installed the rear bump stops wrong! I installed the 2.5" poly stops over the axle and left the stock rubber ones in place, since they were attached to the upper u-bolt plate. I've since cut off the bump stock extension from the frame and attached the poly stop directly to the frame. I still use the stock bump stops and currently have 1.5" of blocking to limit the compression for the shocks and rear drive line.

The higher arched rear springs were causing some rear axle wrap under acceleration. The rear locker probably doesn't help matters, either. Anyway, I debated on what to do about this and decided to try a rigid traction bar. It consists of three main parts, a bracket that replaces the stock bump stop plate under the u-bolts, a bracket that attaches to the spring hanger, and a threaded steel bar with poly urethane bushings on both ends. Installation was easy on the driver's side. The passenger side is quite tight with the gas tank in the way, and I had to bend the lip of the tank up a bit to get room for the installation. The rear bracket is taller than the stock bump stop, leaving only a few inches of travel, so I ended up cutting the upper bump stop extension from the frame. This took about 1 hour per side with an air saw. Then I drilled and tapped a hole in the frame to accept the mounting stud on the polyurethane bump stop. Now, I've got loads of room for suspension travel.

Now that I'm running the Alcan rear springs, with integral anti-wrap leaf, I no longer needed the bars and they've been sold.

[Return to the top]

![]()

Summary:

I spent about 2 days to do the rear end, another 4 to do the front and a day per side for the new body mounts. Most of that time was spent cleaning off the years of grime and rust, priming, painting, and waiting for the paint to dry. The work was done in my driveway, with a Hi-Lift jack, 2 jack stands and a hydraulic floor jack. An 1/2" air impact wrench is invaluable for removing and installing the spring pins and U-bolts. An adjustable torque wrench helps to tighten parts to spec. Putting 100 ft-lbs of torque into 16 U-bolt and 12 spring hanger is a workout! I did purchase new U-bolts but was able to re-use the old ones. The new bolts are about 1" longer than stock and hang down too low and I didn't feel like cutting them off, so I'll keep them for spares.

- Cost:

-

Springs+shocks: $450 Urethane spring bushings: 20 Drag-link: 125 S/S brake lines: 75 Cleaner and paint: 25 Body mount/lift: 35 Adjustable Torque Rod 70 ------------------------------ Total: $800

- Rating:

-or-

-or-

if you have an assistant!

if you have an assistant!

Now that I've put a few (thousand) miles on and off-road with this setup, I've very pleased. Articulation is great, the on and off-road ride is excellent. Compared to the stock springs (which were very harsh IMHO) this suspension is great. It is very solid, no squeaks (yet) or rattles. I've noticed the front right spring has settled a bit quicker than the left (its the flatter of the two springs, due to the offset differential). I tried using a slightly longer front spring shackle to even out the height and then got it level by pulling a leaf out of the driver's side and adding a leaf to the passenger side (what the heck, it works and cost next to nothing!). The rear-end sag was gone, but now has returned due to a heavy bumper/spare tire carrier hanging out back. The addition of the Warn winch helped pull the front back down. I'm basically waiting until I get all the heavy bits attached to the truck before trying to balance anything.

If you are looking into lifting your vehicle, you should be sure to check out your state's motor vehicle regulations. My 4Runner is registered as vehicle type VA (various). THere is also the PK (pickup) class and both those then qualify for the GVWR frame height instead of the lower passenger car limits. With a 4800 pound GVWV, I'm legal to 30 inches ground to frame:

Back to my 4Runner page.

![]()

Visitor # 159134 since 18.MAR.2002

[Last updated: 09.October.2024 ]

===>>

===>>