VW Diesel Tachometer

SEARCH and TRANSLATE

![]()

Contents:

- Introduction

- Digital Tachometer

- Analog Tachometer

![]()

Introduction:

Ever since I've owned my diesel Caddy, I really wished it had a tachometer. The one option that is available on later model VW diesels is the "W-terminal" alternator. This alternator has an extra terminal (labeled "W") that allows an RPM-proportional signal that can drive a dash-mounted tachometer. It is common on the turbo diesel models and requires a full gauge cluster swap to have the tach replace the stock clock. The "W-terminal" also is used to drive the "upshift" indicator that is apparently used on certain '82 and later models.

Unfortunately, my original '81 alternator is not the "W" type and it is still working fine, so I don't really want to replace it, same with the instrument cluster. The alternator is driven off the engine by a v-belt, so the readings provided by the tachometer are probably not really accurate. In any event it would have to be calibrated in some manner (I guess by a mechanical tach?). So, I decided it was best to design a fully digital tachometer system to avoid all these problems.

[Return to the top of this page]Design:

One of my old engineering projects I worked on at NASA involved using optical shaft encoders to pick up shaft speed and rotation for use in position sensors. These encoders use a series of concentric circles of alternating light and dark marks to detect motion. For speed only, one set of marks is sufficient.

In the case of the VW diesel, the injector pump and cam shaft are driven by a toothed belt off the crankshaft. The crank shaft sprocket is 1/2 the diameter of the rest of the sprockets, so they spin at 1/2 the engine RPM. The crankshaft sprocket is not easy to get to, but the one on the fuel injector pump is accessible by an existing hole in the timing belt cover, at least on my A1/1.6D engine. Since the injector pump sprocket is turning 1/2 speed of the engine, it is necessary to have the pickup wheel make two on-off cycles per revolution.

I fabricated the pickup wheel from a sheet of stainless steel sheet metal. I sized it to fit inside the sprocket on the fuel injection pump, this made the outer diameter 118mm with a 43mm hole cut out of the center. I masked off two opposite quadrants and spray painted the remainder with flat black enamel paint. The wheel is attached to the sprocket on the fuel injection pump with a flexible adhesive. In the above picture, you can see one black (non-reflective) quadrant just below and to the left of the retaining nut on the injection pump pulley. The two reflective quadrants are visible just under the A/C hose that runs across the middle of the picture.

Conveniently, there is a rubber plug in the timing belt cover at just the right place to allow the photo-sensor to "look at" the bottom of the injector pump sprocket. I trimmed the mounting tabs on the sensor until it was 3-5mm away from the surface of the pickup wheel. I cut the center of the plug and then glued the sensor into the plug. The entire plug/sensor may easily be removed from the timing belt cover if needed.

Once the sensor was in place, I created a mounting hole for the digital meter in the dash. To the left is the stock emergency flasher switch, to the right is the fog light switch I added. I may end up tilting the display upwards a bit for better visibility. Here, you can see it registering 779 RPM at idle. The nice thing about this digital tach setup is that it is precise and no calibration is required, the accuracy is built into the design. This tachometer also reads out to the individual RPM, not just 100's like run-of-the-mill digital tachs.

The wiring for this design turned out to be deceptively simple. The photosensor has 4 terminals, and they were different than the Omron data book I had. The book describes them a Anode, K(c)athode, Emitter, and Collector, but the sensor had +,-,L and Out. After some trial and error, I found that the internal LED was connected internally to the + terminal and I had to add a current-limiting resistor between the L and - terminals. I used a 620 ohm resistor which limits the current to about 25mA. Likewise, the Out terminal is an open collector output and by tying it to + through a load resistor (620 ohms) gave me a nice 0-12V swing on the output and again about 25mA of current. I soldered the resistors directly to the terminals on the sensor, then ran 3 wires for +12V, ground and output through the firewall to the panel meter. I spliced into the radio power for +12V and ground (switched w/ ignition) and hooked the power and signal to the meter. I used 1/2 watt resistors for this application, and selected a value to limit the current to above value. From the photosensor data sheet, resistance values up to about 1K ohms should produce acceptable current values, don't go any lower than 600 ohms, though.

[Return to the top of this page]Parts List:

Below are the parts I used in this project. I ordered the tachometer directly from Acculex (see link below) and the photo-microsensor was ordered from Digikey along with a very informative Omron Application Guide (highly recommended). The pickup wheel material was purchased at a local hardware store and the other parts were out of my well stocked parts box (but are readily available):

AcculexDP-680-RATE Rate Meter/Tachometer- $90OmronEE-SB5 Reflective photomicrosensor- 5-12 (I used the EE-SB5V but others will work)Optical pickup wheel, s/s sheet metal - 5Misc. wire and resistors - 3 -------------------------------------------------- Total - $88-95

If you would be interested in making your own photo-sensor, you may be interested in the following web page:

Basically, you are looking for a device that will turn on and off with either a change in reflectivity or by physically interrupting the optical path with some sort of slotted wheel. Usually, this consists of a light emitting diode (LED) that provides the illumination, and a phototransistor that senses the presence or absence of that illumination, To avoid problems with stray light sources, infrared is preferred over visible light, and the sensitivity or the photo transistor should be closely matched to the output of the LED. LEDs tend to have a rather narrow output wavelength and also beam width (think of them as tiny lasers), It is important to collect and focus the light out of the source, onto the target and then back to the sensor. While it is possible to make your own photo-sensor, I felt for $12 (actually only $8.50 when I bought mine) my time was better spent on the rest of the system than fooling with more discrete components, etc.

A key feature of these optical sensors is the use of infrared LEDs and photo transistors. This both prevents interference from stray external light sources and by having the two components match for a specific frequency of radiation, they are even more immune to interference. Because of this, you won't see any visible light coming from the LED when its operating.

It seems the Acculex rate meter is no longer available, but here's an option based on a hall effect sensor that may work. With the hall effect sensor, no need for the optical sensor and reflective disc. You may need to add some magnets to get the correct number of pulses per revolution.

[Return to the top of this page]Theory of Operation:

After designing and installing the digital tachometer described above, and publishing this project on the world wide web, I had a few readers ask about applying this design to an analog tachometer. In order to see what changes are required for an analog tachometer, it is necessary to understand a bit about how they work and compare that to how the digital tachometer (or more correctly rate meter) that I already had works.

Any rate meter simply measures the rate at which some event occurs. Usually this is done by counting the events (contact closures, electrical pulses, etc.) for a given period of time (known as the integration interval) and then simply dividing the number of events by the time to get a rate. In my case, I had a rate of 1 pulse per engine revolution and by using a rate meter calibrated in events per minute, I could display revolutions per minute.

In a spark ignition engine, tachometers typically use a somewhat different mechanism to obtain engine speed. Since the ignition is firing the spark plugs, there is a handy signal source present off of the ignition coil primary (in older vehicles at least) that is in the form of a square wave (0-12V). If you know how many cylinders and assuming a 4-stroke engine, which takes two revolutions to complete a full cycle, you can calculate the relationship of ignition pulses to revolutions as follows:

PulsesPerRevolution = NumberOfCylinders / 2

After market tachometers are often equipped with a selector switch on the back to choose 4-6-8 cylinder operation. This simply scales the input based upon the above formula. So, in a typical 4-cylinder VW gasoline engine, you'll have 2 ignition pulses per revolution. So the first modification to my digital tachometer circuit is to up the input pulse rate from 1 to 2 (or more) pulses per revolution.

Unlike the digital rate meter described above, the analog tachometer is usually built up out of an electro-mechanical current meter and some sort of input conditioning circuitry. Instead of integrating the input signal over discrete time intervals, the mass of the meter movement itself is used to continuously integrate the input pulses. Thus, if the meter takes 10mA to swing full scale, if you were to switch the current between 0 and 10mA at a fast enough rate, the meter needle would read out the average of the on and off cycles. In order for this to work, it is necessary to condition the input signal to provide a repeatable output signal given an possibly varying input signal.

The input circuity is used to send calibrated pulses to the meter, usually done with what is known as a one-shot timer. For purposes of discussion, assume the one-shot timer send out a 1mS wide pulse for every input pulse (of varying duration) and the current is calibrated to the 10mA needed by the meter. If the input pulses come at the rate of 10/second (or every 100 mS), the meter will "see" an average current of 1/100 * 10mA or 1% of full scale. If the input speed is upped to 200/second (5mS), then the meter will "see" 1/5 * 10mA or 20% of full scale. Upping the input frequency to 1000/sec will give a full 100% reading on the meter.

- The following web page has a good description of just such a design:

However, I'm not very interested in designing a tachometer from scratch (been there, done that, bought the T-shirt) I just want design a circuit to drive one. One subtle and not so obvious difference between a digital rate meter and an analog tachometer is in the input. Since the tachometer is designed to be driven off of the ignition primary of the engine, it has a very strong input signal (i.e. low impedance) and the load of the tachometer on the ignition is trivial. A digital rate meter on the other hand is most likely designed to operate with high impedance signals and thus probably has a suitably high input impedance (10 MOhms is typical). So, simply hooking up the output of a photo sensor to any run of the mill automotive tachometer may not be successful.

In my case, I was originally using an internally amplified photo sensor and while it easily drove my digital rate meter, it had some trouble with the large tuneup tachometer I had at home. The tach would invariable read about 2/3 the value of the digital meter. It turns out the relatively low input impedance of the analog tach was dragging down the output of the sensor, which caused the RPM reading to fall. While I was only operating the photo sensor at about 1/2 its rated current and probably could have pushed it a bit harder, I felt that design was too marginal for comfort, possibly shortening the life of the component in the elevated temperatures under the hood.

So, I set about making more extensive modifications to the design as described below:

Analog Tachometer Design Modifications:

So, while a digital tachometer is really neat, there are a few drawbacks:

- Digital readouts are harder to interpret quickly while driving, i.e. finding exact shift points

- This readout module is not back-lit, making it invisible in the dark, I could not find a good way to backlight the display.

- It is a bit pricey, over 80% of the cost of this project

Anyway, to accommodate an analog tachometer, designed to operate off a 4-cylinder gasoline engine ignition system, a very simple change is required. By simply laying out 4 dark and 4 light segments (instead of 2) you'll make a wheel that produces 2 on-off cycles per revolution, exactly duplicating a 4-cylinder spark ignition engine. That's the easy part.

If you are lucky, and have a good high impedance analog tachometer, you might be able to construct a circuit as shown below and have it work. Note the use of the amplified EE-SB5V photo sensor. Dropping the values of the two resistors to about 500 ohms would push the input and output currents up and hopefully drive a decent tachometer.

Here's a typical schematic of how such an EE-SB5V setup might look.

This was drawn by Job Oberio

For a more universal solution, I decided to take a slightly different approach. Since the added cost of the internal amplifier in the EE-SB5V was both substantial and inadequate for this application, I instead chose the lower cost EE-SB5 (non-amplified sensor). Below is a sketch of what the revised circuit looks like:

(click to download a larger version)

- The resistor on the EE-SB5 LED is sized to provide between 20 and 50 mA (max.) to the sensor, I chose 620 ohms, since I had one in my parts drawer.

-

The resistor on the EE-SB5 photo-transistor is sized to provide ~20mA

load on the output 620 ohms is about right for 20mA on both sides and

power rating of about 1/4 to 1/2 watt (i.e. I^2*R = 0.020 * 0.020 * 620

= 0.248W)

- However, in conducting some experiments with the non-amplified EE-SB5 detectors, I found that there wasn't enough current gain (known as beta) in the photo transistor to drive anywhere near 20mA on the output, so I had to increase the resistor to about 33K ohms to get a decent voltage swing

- Transistors are essentially current amplifiers, in this case, the input current is due to infrared photons from the LED hitting the exposed base of the transistor, knocking electrons free, which creates the current flow; in this case I was seeing perhaps 0.35mA flow, so 33K resistance gives about a 12V signal.

- Note: for a given amount of current, the voltage drop is related to the resistance as in V=I*R

-

Unfortunately, this rather high output resistance created another

problem when trying to drive an electro-mechanical tachometer, with

perhaps 10-100K ohms input impedance:

- This extra loading (when compared to a 10 Mohm digital meter) is enough to pull the output signal down next to 0.

So, the solution was to add a second stage of current gain similar to the EE-SB5V, but at less cost and without adding it in the sensor itself. So, I returned to another old design solution and the venerable 555 timer. You'll notice it is the same chip used in the previous analog tachometer circuit, but in this case I have it wired up as a Schmitt trigger to both clean and boost the signal up into the 100mA range.

- The following web page has an excellent tutorial on 555 timer operation

Adding this additional circuitry requires the addition of a small electronics box to the system, but this box will provide a nice place to connect things up at. The bipolar Schmitt trigger can drive about 200mA loads and has no trouble with the large shop tachometer I'm testing with. The signal is a nice clean square wave and seems to work at both the lower and upper RPM ranges. And this circuit allows an un-altered analog tachometer off of a gasoline (spark ignition) engine to work off of a diesel engine.

Other Applications (i.e. electric vehicles):

A number of these tachometer drive kits have been successfully adapted to work on other than VW diesel vehicles. Among those applications have been on vehicles converted to electiric operation and to marine and stationary diesel engine applications. All those applications are similar in that there is no ignition type signal available to drive the tachometer. As far as the tachometer signal generator is concerned, it does not care what sort of moving equipment it is connected to. If it rotates, it can generate a signal proporional to the RPM and feed that to drive an analog tachometer. In these applications, a custom pickup wheel and sensor mounting bracket would of course need to be fabricated by the end user.

Tachometer Kits:

We have a limited stock of items such as steering and driveshaft spacers, Bilstein shocks available. Let us know what item(s) you're looking for, where and how you'll want them shipped to and we'll get back to you with a shipping quote and purchase information:

| 4Crawler Offroad contact link | MissingLinkZ contact link |

Since there is enough interest in this circuit, I am offering this as a simple bolt-on kit (actually no bolts would even be required).

Kit options include:

-

"Bag of parts" w/ instructions -

supply your own tach:

- Cost: US$60.00 + shipping (US=$8.00, International = $24.00), CA residents add sales tax

- Some electronics soldering experience required (see instructions below)

|

|

| Order a parts kit for US delivery | Order a parts kit for International delivery - Include phone number in "Note To Seller" field for customs form |

-

Fully assembled electronics package, w/

wiring harness and pickup wheel, ready to hook up to your tach:

- *** At the present time, fully assembled kits are not available ***

-

Cost: US$120.00 + shipping (US=$8.00, International = US$24.00), CA

residents add sales tax

- Allow 6-8 weeks fabrication/testing time (currently not available)

- Specify if using a VW in-dash tach or external tachometer

|

|

| Order a parts kit for US delivery | Order a parts kit for International delivery - Include phone number in "Note To Seller" field for customs form |

- Either of the above two kits are available w/o the reflective pickup wheel for US$5.00 less for custom applications.

- Complete systems (w/ tach) ready to install (price varies with tach option - see below)

-

If you

would be interested in a kit, please e-mail me and let me know

- Missing LinkZ is taking orders and shipping kits

- We work with PayPal or accept check/money order (contact us for our address)

- Custom (non-VW) applications available, contact me with your specifications.

Here are some options for tachometers:

-

A used OEM VW gas tachometer from suitable vehicles, replacing the

clock in the instrument cluster

- Approx. $100-150 for a used cluster on eBay

-

0-8000 RPM. 270 degree sweep at the low end

- Approx. $50 on up depending on size and features

-

0-5/6000 RPM at the high end

- Approx. $80-100 on up depending on size and features

-

A lower cost digital tach (100 RPM resolution)

- Approx. $90 on up depending on size and features

-

A higher cost digital bar-graph tach

- Approx. $100 on up depending on size and features

- Note the VW diesel engine tops out about 5000 RPM

Various sizes are available:

- Factory in-dash tachs from gas-powered VWs

- 2-1/16" or 2-5/8" bezel mount - would fit well in an in-dash application

- 2-1/2" or larger dash-top mounts

One problem with replacing the clock with a tachometer is that you lose the clock.

[Return to the top of this page]Tachometer Kit Installation Instructions:

- Remove timing belt cover (4 bolts)

-

Attach the pickup wheel to the injector pump sprocket

- See: Picture 1

- Thoroughly clean the inside of the injector pump sprocket, you may want to spray a bit of flat black paint on the two sprocket alignment holes if they are shiny

- Be sure to line up the two holes with the sprocket alignment holes before gluing in place

- For adhesive, we use "Automotive Goop" or a good high temperature, oil-resistance silicone adhesive-sealant or something like JB Weld will work as well.

- Clamp the pickup wheel in place until the adhesive cures

- Note that these photos are of the prototype pickup wheel. The current production model has 3 holes in it to allow insertion of the pump timing lock tool and to access the lower pump retaining nut and bolt for timing adjustments. So you should be sure and align the holes in the pickup wheel with those holes in the sprocket.

-

Pop out the small rubber plug and install the optical sensor to the

inside of the belt cover

- This applies to the Volkswage A1 diesel engines, some later models may require the drilling of a 5/8"/16mm hole over the injector pump sprocket, roughly over the center of the spokes.

-

- Check the clearance between the pickup wheel and sensor, ideal clearance is approx. 5mm.

-

With the cover installed:

- Measure from the outside of the cover in to the pickup wheel (Picture 2a)

- Measure the length of the photo sensor from its mounting point (Picture 2b)

- The difference should be 1/8" to 1/4"

- If not adjust with the sensor or the timing belt cover with washers

- If placed too close to the wheel, the sensor will be damaged

- If its too far away, the sensor may not get a good signal

-

Make sure the cover is securely fastened and doesn't vibrate

excessively when the engine is running

- If you don't have all 4 mounting bolts installed, replace them before installing the sensor

-

You can adjust the photo sensor clearance by moving washers on it or

the timing belt cover

- If needed, you can also bend out the face of the timing belt cover for more space.

-

Once the depth is set, install the sensor and tighten down the

retaining nut (Picture 2c)

- Note that the old style pickup wheel design is shown in this image, the new version has holes to allow for locking the pump sprocket in place for timing as well as an access hole for the lower pump mounting bolt, click here for an image of that new design part. When installing the new wheel, be sure to align the two full holes with the alignment holes in the sprocket.

- Take care to orient the sensor so its long axis is aligned circumferential with the rotation of the pickup wheel

-

Re-install the timing belt cover

- If in doubt on the sensor clearance, crank the engine over manually and check the sensor and pickup wheel for signs of contact

- Don't start the engine until you are positive the sensor won't contact the pickup wheel

- And most importantly, BE SURE THE BELT COVER IS SECURE, make sure all the bolts and spacers are in place and tight before starting the engine and driving. You do not want the cover to come loose while driving as it or one of the mounting bolts can easliy come loose and damage the timing belt.

-

Route the wire from the module to the sensor and attach the supplied

connector

- See: Picture 3

-

Connect the +12V supply wire to the fuel cutoff solenoid valve on the

injector pump (blue crimp-on connector just visible in lower center of

image) and connect the ground wire to a suitable ground point, I used

one of the bolts that attach the throttle cable bracket to the pump.

- See: Picture 4

- You may want to add an in-line fuse for the power line of 1/2 to 1 amp.

- Also, be sure you have a clean power source, should have no glitches (if so, consider adding a noise filtering capacitor of a few uF) and be sure the voltage is no higher than about 13 volts. Sometimes when alternator regulators start to fail, they can put out very high charging voltages (14 volts or higher) and this will damage the IC in the signal generator box and it will also kill your battery in short order.

-

Find a suitable mounting location for the electronics module; the

passenger fender wall is usually available, I had an un-used bracket on

the fender wall.

- See: Picture 5

- Be sure to mount the electronics box in an area where it will be protected from water and also make sure to either seal it up water tight (with silicone sealant) or mount it with the wires downward so any water that might get into the box will drain out.

-

Route the remaining wire through the firewall (the hood release grommet

is good for this) and under the dash

- This wire supplied without connectors to allow passage through the firewall.

-

Now, strip and connect the wires as follows:

-

Green wire to the tachometer

"RPM" or ignition input

- If using the VW gas tachometer, you'll need to connect this wire to the "B" terminal on the tach in place of the stock flexible wiring connection (see write-up on OEM tachometer installation, below)

- If you do not use or have an "upshift" light and/or an RPM-sensitive oil pressure indicator (such as on the A2s) then another connection option is to remove the wire from the "W terminal" on the alternator and connect the green wire from the tach generator box and you are done. That signal is wired back to the tach input wre on the factory cluster.

-

For use with non-OEM tachometers, the following wires are available:

-

Black wire is ground

- If not used, wrap this wire in tape to keep it from shorting something else out.

-

Red wire is switched 12V if

soldered to the "+" terminal on the circuit board

- If not used, wrap this wire in tape to keep it from shorting out.

- The yellow or white wire is unused

- If using an aftermarket analog tach, you'll probably be connecting it to power and ground, so just run all the sender wires up to the terminals on the tach and it should be ready to go (you may need to supply a dash light wire for the gauge illumination)

-

Black wire is ground

-

Green wire to the tachometer

"RPM" or ignition input

-

For testing, you may add an LED as shown on the schematic, to check

that the system is working properly:

- The LED will flash in time to the engine revolutions, you should see about 25-30 flashes per second at idle.

-

Assuming your tachometer has not been modified, the system should need

no calibration.

- I found on mine, the needle was pointing about 30° below the "0" mark, so I had to pull the needle off and carefully reposition it to point to "0" at 0 RPM, I'm not sure why my needle was off like this.

- After a year or so of use, you may notice the tachometer needle start to jump a bit at higher RPMs. If this happens, remove the timing belt cover and clean the face of the optical sensor. Its infrared optics are fairly tolerant of dirt, but if it gets very dirty it loses sensitivity and high response speed. Use a water-based window cleaner and soft rag to clean it.

After a few years of use, I found a totally unexpected benefit of this tachometer design. I decided to install a cruise control on my VW diesel and guess what, it needs an engine RPM signal to operate - BINGO!

[Return to the top of this page]OEM Tachometer Installation:

If you currently have the two gauge cluster with the analog clock and you are planning to use an in-dash tachometer in your VW diesel, you have a few options:

-

The first is to locate a VW diesel with the real diesel tachometer that

takes its input from the "W" terminal on the alternator and

use that (this assumes you have an alternator with a "W"

terminal).

- Most commonly found on the Jetta turbo diesel models.

- The "W" terminal is also used to drive the "Upshift" indicator

-

Another tachometer option is to use a VW gas tachometer and the proper

alternator, i.e. one with the"W" terminal, and modify the

tachometer as described here.

- This technique basically recalibrates the tachometer to handle the higher output frequency of the alternator W-terminal signal

- Here is a copy of the old writeup that was passed on to me by the author, Mike Musick, and is available here, although the information has not been verified and some folks have reported difficulties getting the modified tachometer to work properly following these instructions.

- Here are some other links on the subject that may be of help:

-

There is a company that

sells either convertor kits for the W-terminal or a flywheel pickup

unit to drive a gas tachometer (model DSL-1).

- Apparently this kit does not work properly with at least the A2 gas tachometers due to input signal differences.

- Or, you can use the previously described analog tachometer circuit to drive the un-modified gas tachometer and avoid the calibration hassles.

So, your first step is to locate a suitable tachometer to use for the conversion. It is best to obtain an entire instrument cluster if possible. They can often be found on eBay. For an A1/Mk1 VW, use one from from an '84 GTi model. For other model VWs, you would want to use one from a similar model to ensure proper fitment in the in-dash instrument cluster and for other makes of vehicles, find a compatible model vehicle to obtain a tachometer from. Other applications are for vehicles which have been converted from gasoline to diesel engines and even for vehicles converted to for example electric drive.

Disassemble the cluster by removing the lamps (save them for spares) and then the flexible circuit board. Remove the tachometer and the fuel and water temp gauges that go with it. One advantage of the getting the entire cluster is that you get a new housing without the hole drilled to access the analog clock stem. Another advantage is that you are getting a whole boat load of spare parts, light bulbs, odometer gears, etc.

- Here's a good writeup on removing the instrument cluster if you need some pointers:

-

//www.4130-products.com/step/remove/

- I do mine a bit different:

- - I reach up underneath and unscrew the speedo cable (assuming you have a screw-on connection)

- - Don't forget the pull-out headlight switch knob, there is a button underneath the switch to release the knob and shaft (I like to insert the shaft back in and gently push the switch to the off position w/o pushing the shaft back into the switch)

- - Then if the cluster won't come out easily, some trimming of the back opening of the dash cutout can make it much easier. My '82 came out very easy, but my '81 had a lot of flashing left from the molding process and I had to trim the opening a fair amount to get it out (none of the trimming is visible with the cluster in place).

- I do mine a bit different:

In any event, you'll probably want to use your old speedometer, the old wiring and replace the clock side of things with the tachometer. The fuel and water temp gauges may be located differently, but should still work. The only modification needed is to carefully trim back the "tachometer" "W-terminal" connection from the tach, tape it off then connect a separate wire to the terminal on the tach which in turn gets connected to the tachometer pickup signal.

- Note: For those who are curious, I stuck an oscilloscope on the "W-terminal" and found that it delivers a fairly decent square wave signal, 0-12V or so, at about 25 pulses/revolution. This is an approximate value as I also had my accurate optical signal on the second channel and noticed the "W" signal was not locked to the accurate signal. If you connect it to the gas tachometer, you'll get abnormally high RPM readings, I saw about 4-5000 RPM at idle. But this is a good way to test if your gas tachometer is working.

Shown below is a VW A1 diesel instrument cluster. Other models may look different but the basic idea is to pull the cluster out, remove the clock and install the tachometer in its place. As far as the wiring changes, compare the clock and tachometer wiring and identify the power and ground connections on both. Then the extra wire that the tachometer has is the one that you replace with the output of the tachometer signal generator. Now on to the A1 details...

-

Remove the stock diesel instrument cluster

- See: Picture 1

- The green arrow points to the original clock, this gets removed to install the tachometer

- The red circle is around the clock's constant 12 volt power connection, this is not used with the tachometer, it uses switched power so it turns off when the engine is off.

- The blue circle is likely the clock's ground connection, this is also not used with the tachometer

- The yellow oval is around the area where the cluster wiring plug mates with the cluster to bring in all the various signals and voltages to the cluster. So power for the tachometer as well as the W-terminal signal from the alternator (if factory installed) comes in via this connector.

-

Remove the various instruments from both clusters

- See: Picture 2

-

Note, the gas cluster bezel (bottom) lacks the clock setting hole and

hardware

- See: Picture 3

-

Don't forget to transfer the diesel indicator light legend to the new

bezel

- See: Picture 4

-

Install the gas tach and the diesel flexible circuit, then carefully

trim the mylar material back from the stock "tachometer"

connection, tape it off to prevent a short circuit, then connect the

new wire (green in this picture) to the tachometer "B"

terminal (circled in green).

- Note: As pictured, I connected wires to the stock "W-terminal" (yellow wire - yellow circle) and the clock's +12V circuit (the other green wire - red circle) for conducting some experiments. Simply wrapping the contact in electrical tape is sufficient as shown in the light blue circle).

- So what functions did I use the old W-terminal and clock 12 volt connections for? Well, I used the W-terminal signal to determine the relative frequency of the W-terminal pulses vs. the ones from the tachometer signal generator as noted just above the photos in this section. And the clock power? Well, I used it to supply power to the 2" round VDO clock I put in a center console. Instead of reinventing the constant 12 volt clock power signal, I merely used what was on the back of the cluster to feed the new clock.

- Obviously, you don't need to do this unless you also have plans for those signals. If not needed, simply wrap those circuit ends in electrical tape to prevent an accidental short circuit and push them out of the way.

- See: Picture 5

-

Once everything is back together, slip the cluster back into the dash

and re-install the fasteners.

- See: Picture 6

-

Start the engine and check to see if everything is working.

- You'll notice I swapped to the GTi speedometer/odometer, since my old diesel odometer basically fell apart in my hand when I took it out. I tried repairing the broken drive gear, but the plastic frame was cracked where the gear that connects the trip meter and odometer was and it fell out. I did take care to set the GTi odometer to the same mileage as my old odometer (and I'll keep it around for backup). I figure I added 30MPH to my vehicles top speed, too, instead of the meager 90MPH top end, I now have 120!

- See: Picture 7

NOTE:

You can follow the above proceedure to swap a tachometer for a clock in a gas engined VW as well. Just ignore all the wiring changes I had to do for the diesel conversion. Also if you are swapping a diesel tach into a diesel cluster, then again, you don't have to make any wiring changes, either, since the W-terminal RPM signal is already present at the tachometer. Its only when swapping a gas tach into a diesel that you need to connect the RPM signal generator output to the tachometer input.[Return to the top of this page]

Analog Parts List:

Below are the parts I used in this project. I ordered the tachometer directly from Acculex (see link below) and the photo-microsensor was ordered from Digikey along with a very informative Omron Application Guide (highly recommended). The pickup wheel material was purchased at a local hardware store and the other parts were out of my well stocked parts box (but are readily available):

[Return to the top of this page]OmronEE-SB5 Reflective photomicrosensorOptical pickup wheel, s/s sheet metalConnectors, wire, project box, circuit board and components: 1 x 620-750ohm resistor (this means any resistor between 620 and 750ohms will work) 1 x 33Kohm resistor 2 x 100Kohm resistors 2 x 0.01uF capacitors 555 Bipolar timer May also include a 2nd 620-750 ohm resistor and LED if requested

Parts Kit Information:

First check the parts kit contents (see above) and familiarize yourself with the parts. If not familiar with resistor and capacitor codes, refer to the following for information:

Some of the components may vary slightly from the schematic, for example the 620 ohm resistors are non-critical and anything up to about 750 ohms will work fine. Your kit should include:

- 1 - Photosensor

-

1 - 4-pin connector pair

- Not required, you could hardwire the photosensor directly to the circuit box

- 1 - 555 Bipolar timer IC

-

Capacitors:

- 2 - 0.01 uF filter capacitors

-

Resistors, 1/8 or 1/4 watt

- 2 - 100Kohm

-

2 - 620-750ohm

- 1 Resistor optional, for limiting current to the indicator LED (below)

- 620ohms will give maximum current to the LED.

- If you have a very high heat environment, you might chose a lower LED current as set by the 750ohm resistor.

- 1 - 33Kohm

-

1 - LED (optional)

- Flat side of package indicates the cathode which is the negative (ground) side

- Indicator for tachometer operation

- 1 - PC board

- 1 - Electronics project box

-

1 - s/s or aluminum pickup wheel

- Some folks have used an old CD, painted with black stripes

- Other options are to paint bright/dark strips on a sprocket/pulley/flywheel, etc.

- 2 - flat washers for the connector mounting

- Assorted wire for power, input and output connections

Parts Kit Assembly:

If you purchased the parts kit, you'll need to assemble and test the electronics module.

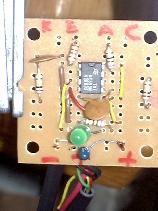

Follow the circuit schematic above for connections and also you can use the parts layout information that is included with the parts kit. You may notice some minor changes between the schematic and the parts layout diagram and photo below. The schematic was drawn up based on laying parts out so they look good on the schematic. The parts layout and photo below are done in a way that makes the wiring and soldering easier with the PCB that is supplied with the parts kit. SO if you want to follolw the schematic to a "tee", feel free to do so. If you want to follow the parts diagram and photo, feel free to do so. There are notes in the instructions below mentioning where differences may be found:

- There are two different types of PC boards used, depending on availability.

-

One is simply a grid of pads:

-

First, start by placing the 555 timer chip in the center of the printed

circuit board.

- May have a notch on the top side or a mark of sorts for the #1 or #2 pin, depending on the part mfg.

- Then, run a bare power wire up the #8 pin side of the board and bare ground wire up the #1 pin side.

- Then insert all the discrete components as desired, arranging them to end up in the hole next to where they will terminate.

-

First, start by placing the 555 timer chip in the center of the printed

circuit board.

-

The other is set up for DIP (dual in-line package) chips like the 555

IC and has more connections made

- First, place the 555 timer and components per the above parts layout

- Note the above photo includes the optional diagnostic LED (green device) and the blue bypass capacitor (optional, use ~1uF tanatlum capacitor if desired) at the bottom center.

-

Don't forget the jumper wire between the #2 and #6 pins:

- In the photo below, the jumper is on the under side of the PCB, and not visible.

- If you want to place that jumper wire on top of the 555 along with the other wires, feel free to do so.

-

Arrange the parts so the opto-sensor wire will come into the top of the

circuit board, the power and tachometer signal goes out the bottom.

-

It makes no difference which side of the opto sensor LED that the

resistor goes on, it'll work exactly the same between power and the LED

or between the LED and ground.

- So choose the side that results in the cleanest installation.

-

It makes no difference which side of the opto sensor LED that the

resistor goes on, it'll work exactly the same between power and the LED

or between the LED and ground.

- Solder all the components, including the 5 jumper wires to power and ground as needed.

-

Solder the opto-sensor to the short end of the 4-wire connector,

trimming it to is sits as close as possible to the end of the

connector, too long and it'll rub on the pickup wheel.

- We find that connecting the Collector to pin 1, Kathode to pin 2, Anode to pin 3 and Emitter to pin 4 works well.

- Be sure to test fit the connector to make sure the sensor is about 5mm (a bit less than 1/4") from the pickup wheel

-

Solder the short 4-wire cable from the long end of the connector and

run it into the box, I drill a hole in one end of the box for the wire

to enter, use a simple end to end connection scheme:

- We use pin 1 = black, pin 2 = red, pin 3 = yellow, pin 4 = green.

- Solder the long wire to power (red), ground (black), and tachometer signal (green) and run it out of the box.

-

If desired the 2-conductor wire can be hooked to power and ground.

- It is handy to connect to power and ground at the fuel cutoff solenoid on the injector pump.

- Otherwise, run power and ground in on the long wire from the dash.

- Alternately, for aftermarket tachometers, the power and ground from the long cable can be used to power the tachometer.

-

Also shown above is an optional 1 - 10uF polarized/tantalum bypass

capacitor (round blue colored part at the bottom - optional)

- For power filtering

- Connects between +12V and Ground

- If you find your charging system has a lot of electrical noise and that affects the tachometer display (like the needle jumping around too much), then feel free to add the bypass capacitor as shown. You can get one at most electronics stores.

Parts Kit Troubleshooting:

Once everything is connected, its time to test the circuit.

- First apply 12V and a ground connection to the circuit.

-

For testing, I use a top from a tin can, painted half in flat black and

chuck it up in a cordless drill to serve and a signal source for

testing the circuit.

- The circuit has built-in high pass filter to clean up in low level input signal.

- It therefore won't respond to static on/off type signals.

- You may be able to use a shiny piece of metal, like the top of the electronics box, to generate a signal by rapidly moving the sensor on and off the metal.

-

The cutoff frequency is around 500 RPM (1000 pulses/minute) so the

input needs to be pretty fast to make it past the filter.

- My cordless drill only runs up to around 350 RPM, so I made the test wheel with 4 pulses per rev, which will "trick" the circuit into seeing twice the RPM.

If the LED blinks with an input signal, you are set, it works!

-

If not, time to troubleshoot a bit...

- Check all the power and ground connections.

- Check the pin 2-6 connection, it should be 1/2 the input voltage, if not, check all the connections to pins 2 and 6, there are a few.

-

Check the Emitter (E) output of the opto-sensor before the 0.01 uF

capacitor. It should swing nearly from 0V to 12V as the sensor moves

from shiny to dark.

- This input will respond to static light and dark signals, it is before the filtering 0.01 uF capacitor.

-

If not, check all the inputs to the sensor.

- There should be about a 12V drop across the resistor on the LED part of the opto sensor. If no drop is observed across this resistor, there is no current in the LED so the photo transistor won't be getting any signal.

- While I usually pot the opto sensor legs to the connector shell, don't do so before you are 100% sure its working.

-

If all these tests fail, double check all the components and solder

connections.

- Check all the 555 pins, make sure the power pins have power, the ground pins are at ground and the input pins (2 and 6) are at 1/2 the supply voltage.

-

If it all looks good, most likely the 555 timer has been damaged.

- You can get a new one at any Radio Shack (p/n 276-1723)

- Note that even a brief power reversal (i.e. +12V to black, ground to red) will blow out the 555 timer IC

- Normal current draw is about 30mA, but if the 555 is dead, you'll only see about 20mA current which is what the opto-sensor pulls.

- If you want the LED to be visible, drill a hole for it in the box lid, install the circuit board and top and once its all working, apply some clear silicone sealant to the lid, LED and where the wires enter the box.

![]()

===>>

===>>

Visitor # 238661 since 17.SEP.2001

[Last updated: 12.March.2023]