These instructions are designed to help the 4wheeler align their own vehicle after installing a lift and also after hard off road use. This method works and was used for the "initial" measurements in the able below.

Alignment Specs, 1994 4runner comparing the home alignment to that of the dealer after a relay rod recall. |

||||||

Wheels |

Adjustment |

L/R |

Initial |

Min. Spec. |

Max. Spec. |

Final |

Front |

Caster |

Left |

2.8 |

1 |

2.5 |

3 |

Right |

1.1 |

1 |

2.5 |

1.5 |

||

Camber |

Left |

-.3 |

0 |

1.5 |

-.5 |

|

Right |

-.5 |

0 |

1.5 |

-.5 |

||

Toe |

Left |

1/32" |

0 |

3/32" |

1/32" |

|

Right |

-1/32" |

0 |

3/32" |

1/16" |

||

Total |

0 |

0 |

5/32" |

1/16" |

||

Note, after dealer alignment, steering wheel was no longer centered. That was corrected at home int he garage later. The truck exhibited excellent drive characteristics before and after the dealer alignment.

|

||||||

Camber: Looking at the truck head on, positive camber is where the wheels lean outwards, negative is inwards.

Caster: This is the rake of the wheel spindles. It should be such that they lean back like the forks on a motorcycle.

Toe: This is the angle of the tires normal to the pavement plane. If the tires are pointing at each other, they are toed in, if pointing away, toed out.

Procedure:

- Pull the truck straight onto a flat surface, turn off the truck and so the steering wheel locks straight.

- Make sure the truck is level. This will require adjusting the torsion bars if it is leaning to one side. This step is important so take your time. Pick a spot on the frame on each side of the truck and measure it against the ground. Adjust until it is level.

- Check the camber with a right angle like this. Although the spec says 0-1.5, I have a -.5 (set by the dealer) and the truck drives very well.

-

If it is not vertical, loosen the cams and adjust them inwards or outwards. NOTE: You want the rear bolts to point outwards more than the fronts as pictured. This brings the caster into where it should be while increasing firewall clearance. You will likely have to roll the truck back and forth to allow the tires to relax as pushing out the rim will flex the sidewalls a bit making it hard to align to the square. You can use a small ruler and easily get to where the distance between the top and bottom side surfaces within .125". (1/8) Here, symmnetry is desireable. If one tire is cambered outwards a bit, so should the other one. You don't want the tires parallel to one another. Toyota's spec is 0 to 1.5 degrees out. Adjust the cams as pictured below, this will get the caster within spec

-

-

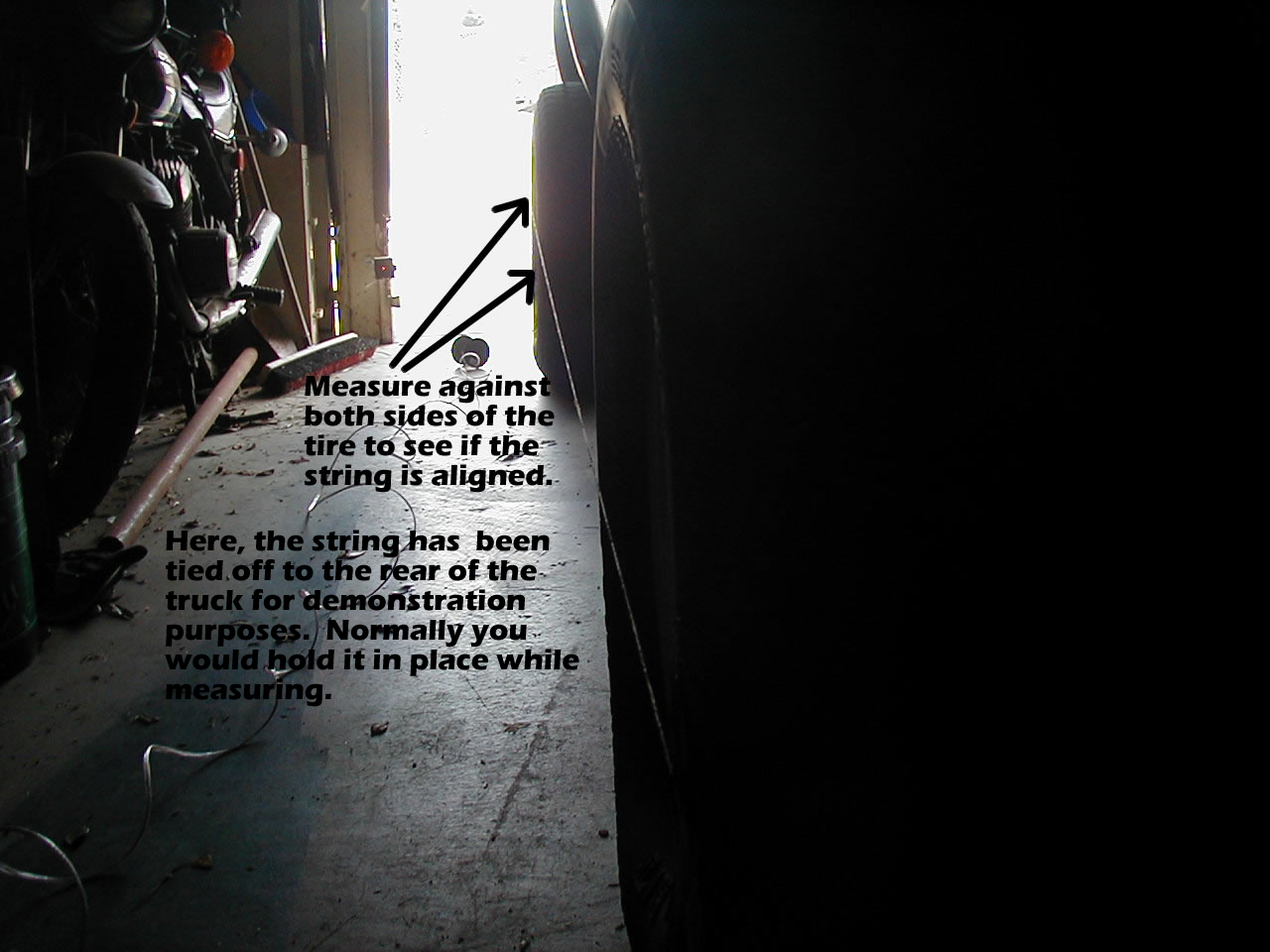

Tape a string to the front wheel and walk with it to the rear of the truck. Measure against the front and rear outter surfaces of the rear wheel. NOTE: The string should not rest flat against the rear wheel due to the front track width being greater than the rear. The string should be the same distance from the sides indicating the front wheel is pointing the same direction as the rear. If it isn't, loosen the adjuster on the tie rod and tweak it until the front wheel is straight. You can use a small ruler and easily get to where the distance between the side wheel surfaces within 0- .0625". (1/16) At that difference, the front wheel is toed in appropriately.

-

- Repeat these steps periodically rolling the truck back and forth to releive tension on the tires between adjustments.. By keeping the steering wheel centered during the forward/backward rolling you ensure it stays centered on the road.

- The inital alignment after a lift can take a while. However, "touchups" can be done quickly thereafter. Also, now when you wonder how the truck will perform if you adjust your torsion bars one way or the other, you can do so without the $50 alignment bill thereafter.