USE OF THESE INSTRUCTIONS IS AT YOUR OWN RISK

When installing this product, the installer is the final manufacturer of his or her vehicle.

Installation and use of this product is at the risk of the installer. SDORI assumes no

responsibility for any damages, to person, property, or any other sort incurred as a result of

the use, mis-use, misunderstanding, inaccuracy or incompleteness of these Instructions, taken

in whole or in part, or the products to which they may directly

or indirectly pertain. The liability of San Diego Off-Road Innovations, LLC, its affiliates,

members and employees is solely limited to the providing a product of accurate dimension. What

the buyer, installer, user, or any other person Does with product purchased from San Diego Off

Road Innovations, LLC is done at their own risk and responsibility. Furthermore, San Diego Off

Road Innovations, LLC does not guarantee the completeness or accuracy of the instructions

contained herein.

- Place truck on jackstands and remove wheels.

- Remove the original ball joint hardware.

Knock the studs out of the joint with a small hammer.

This is done most easily if the joint is pressed

against the arm with a floor jack.

- Unbolt the upper shock hardware.

- Trim the lip as depicted in the above picture.

An angle grinder or 4" cuttoff wheel is highly recommended.

- Put the spacer in place, NOTCH FACING DOWNWARD

and, using a floor jack to control arm height,

align the ball joint and install the hardware.

- Tighten ball joint hardware to 30 fl*lb or 40 N*m.

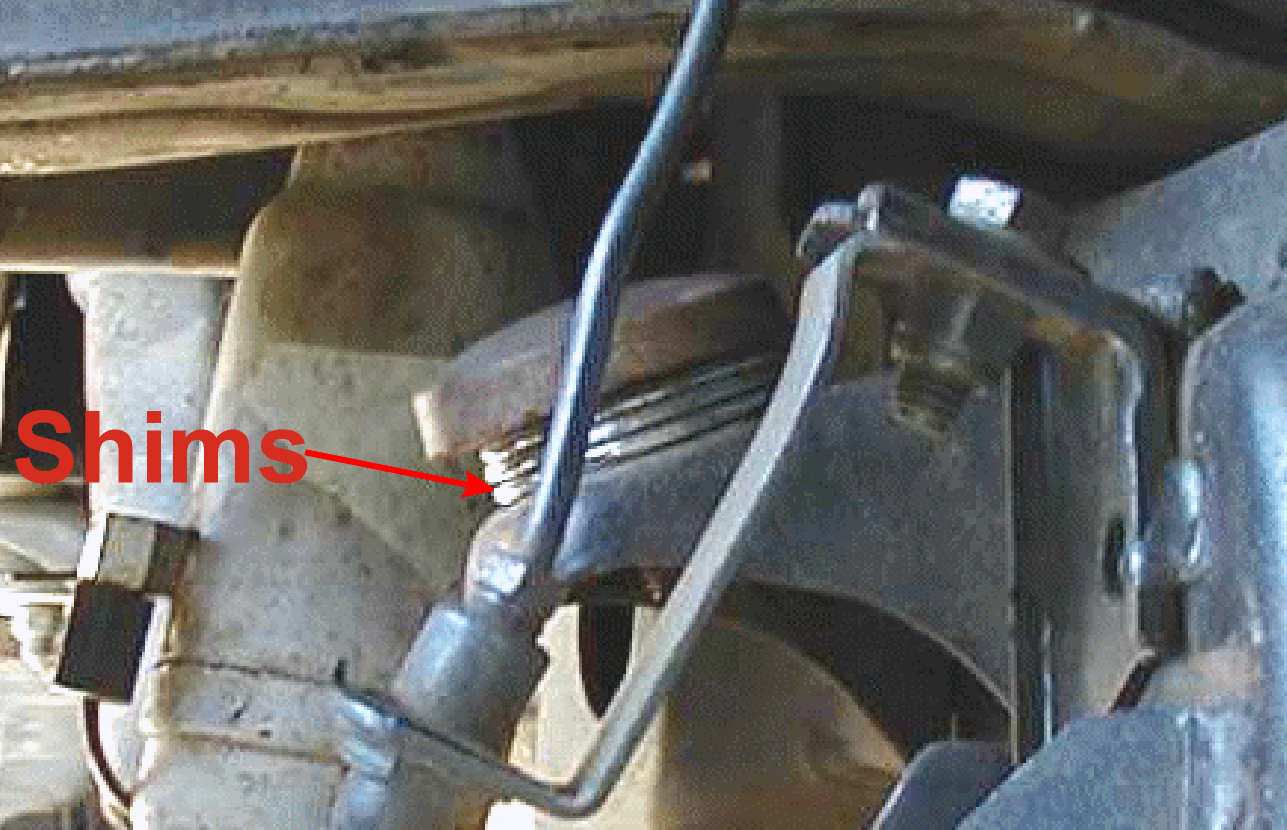

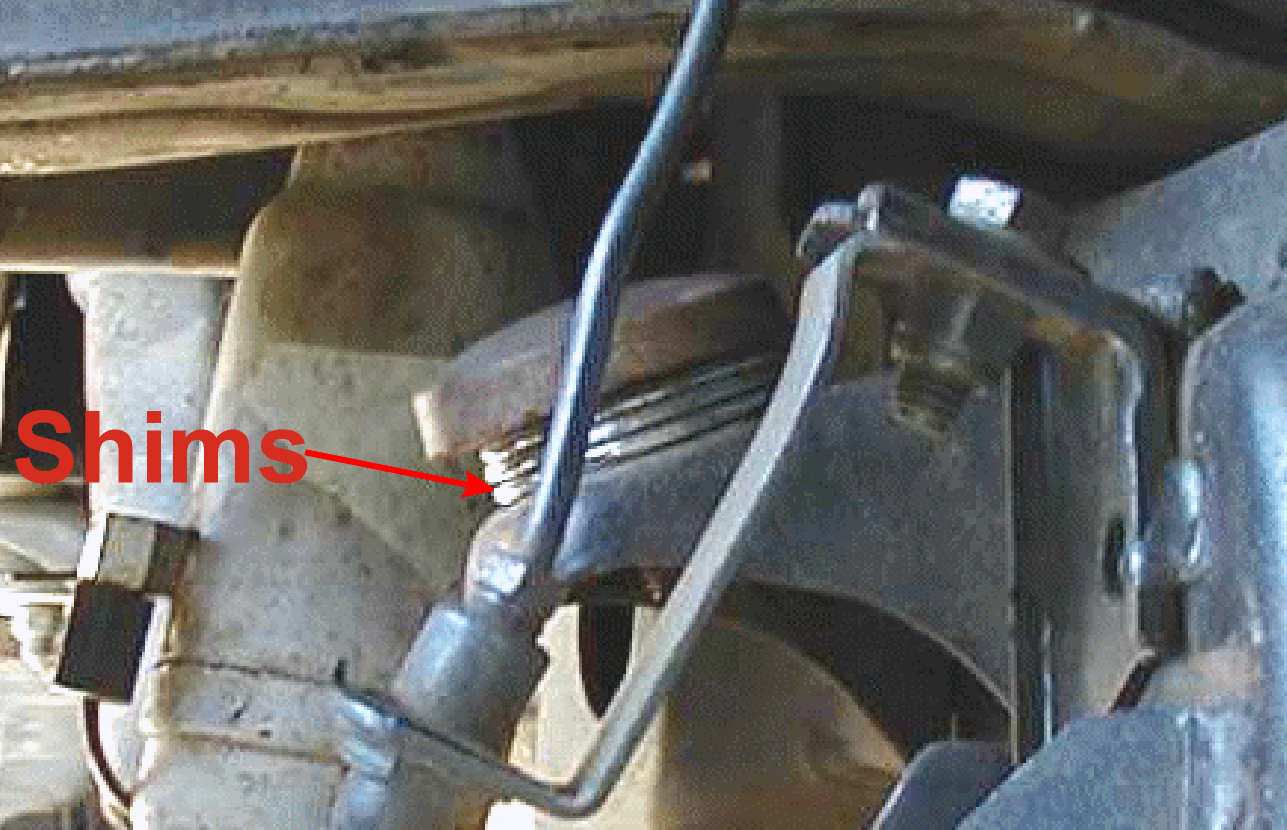

- Extend the shock to see if it needs shimming.

it likely will) Place the appropriate number

of washers to ensure the shock does not limit

down travel.

- Tighten shock hardware.

- Repeat for other side.

- Re-install the wheels.

- Put the vehicle back on the ground.

- For low pro bumpstops only: Shim them .5" with some

washers or use stock bumpstops. Failure to do so could result in

damage to CV joints, shocks, or other components.

13. Re-adjust torsion bars. There

good instructions here.

In short:

Spray

the t-bar hardware with a penetrating lubricant.

-

Wipe

all debris off of the threads.

-

Spray

them again.

-

Jack

up the front to unload the bars.

-

Adjust them with a

22mm wrench.

-

Lower the truck.

-

Bounce the front

end and roll the truck back and forth at least 10 feet.

-

Repeat

until the front is level and at desired height. The measurement between the

fender lip and edge of rim should be about 15-15.5".

14. Get an alignment or save dough by

following these

instructions.

- It has been observed that some driveway alignment adjusting is

beneficial and easy to do. Following these simple steps will make

life easier for the alignment tech who, to be honest, might not be

prepared for a vehicle that is any other than bone stock and only

slightly out of alignment.

- 1st set the ride height in step 12.

- Loosen the adjustment cams on the lower a-arms making a note of

each bolt's orientation.

- Move the lower arms outwards until two things happen. (It

will likely be necessary to lift the front end while adjusting and roll

the truck forward and backward after each adjustment.) One, the tires

appear vertical. Two, all cams are adjusted to mirror those on

the opposing arm and in a position *closely* relative to where they

started. (It is more important that the tires be vertical than the

hardware be exactly relative to it's originating position) For

example, if the driver's side front cam is pointing straight up and the

driver's side rear cam is pointing outwards, the passenger side front

cam should be straight up and rear outwards. If, before

adjustment, say the rears were angles outwards 30 degrees more than the

front, after adjustment the rears should still be outwards about 30

degrees. (again this is not as critical as trying to get the tires

vert.)

- Adjust the toe by loosening the adjusters and rotating.

It's a good idea to lock the steering wheel in a straight

position. What you adjust to one side, do to the other. Typically

about .5-.25" of toe is fine. If you have trouble measuring,

simply attempt to get them straight or angling in slightly.

- You'd be surprised how close one can get these measurements with

just the eye. However, perfection is not necessary, this will

simply get you in the ball part and help to avoid the "blank stare"

when an alignment tech sees his numbers are out and doesn't know

which nut to turn which way. (you'd be surprised how often this happens

with 4X4's)

- You should recheck the height after this. If you find you

adjust the height severely, which is unlikely, and the tires are

clearly off (by the eye), repeat these steps.

14. Re-check hardware torque in 2 weeks.

USE OF THESE INSTRUCTIONS IS AT YOUR OWN RISK

When installing this product, the installer is the final manufacturer of his or her vehicle.

Installation and use of this product is at the risk of the installer. SDORI assumes no

responsibility for any damages, to person, property, or any other sort incurred as a result of

the use, mis-use, misunderstanding, inaccuracy or incompleteness of these Instructions, taken

in whole or in part, or the products to which they may directly

or indirectly pertain. The liability of San Diego Off-Road Innovations, LLC, its affiliates,

members and employees is solely limited to the providing a product of accurate dimension. What

the buyer, installer, user, or any other person Does with product purchased from San Diego Off

Road Innovations, LLC is done at their own risk and responsibility. Furthermore, San Diego Off

Road Innovations, LLC does not guarantee the completeness or accuracy of the instructions

contained herein.

|